SDI PRODUCT

MVR EvaporatorProduct Video

MVR is the abbreviation of mechanical vapor recompression.

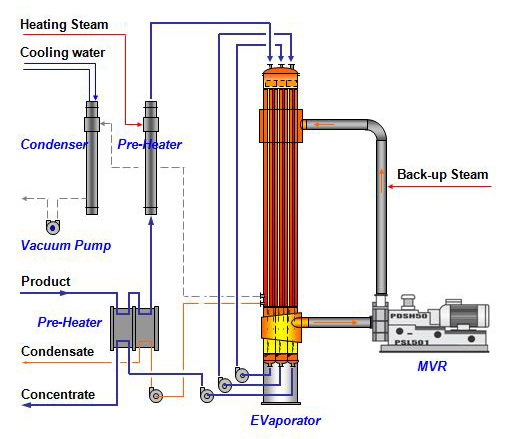

The working process of MVR is to compress the low temperature steam through the compressor, increase the temperature and pressure, increase the heat enthalpy, and then enter the heat exchanger to condense to make full use of the latent heat of steam. In addition to starting of the operation, there is no need to use new steam for heating. The secondary VAPOR is compressed by the compressor, the pressure and temperature are raised, the heat is increased, and then sent to the heating chamber of the evaporator as a heating steam to keep the liquid boiling, and the heating steam itself is condensed into water. In this way, the steam that was originally planned to be discarded turns to be fully utilized, the latent heat is recovered, and the thermal efficiency is improved. The economy of the steam generation is equivalent to the 30 effect of multi-effect evaporation. In order to make the evaporation device as simple as possible and easy to operate, a centrifugal compressor or a Roots type compressor can be used. These machines have a high volumetric flow rate in the range of 1:1.2 to 1:2 compression ratio. The evaporation equipment has a small footprint and a small space required. The cooling system can be omitted.

Advantages and Characteristics of MVR Evaporator

1, Energy Saving: the use of secondary Vapor preheating, no Heat

Waste, Working Efficiency is equivalent of 8 effect evaporator.

2, Environmental Friendly: Equipment only needs Preheat Steam

which brings high economics.

3, High Automatic Control: Equipped withevaporator automatic control system, the

whole system only needs one person working in Control Room for Full Control Coverage,

reducing Labor Costs and Operation Errors.

4, The Compressor Selection: Evaporator will be designed with suitable Steam Compressor mainly from the Roots Compressor and Centrifugal Compressor, in compliance with the Capacity of the MVR System.

Applications:

MVR has been widely applied in various sectors such as Chemical Waste Water Treatment, Chemical Processing such as Sodium Chlorite and Sodium Sulfate etc., Food Sectors such as Glucose, Amino Acid, Dairy and Pectin etc., Herbs Extractions such as Licorice Extract and Stevia Extract and Food Sector such as Fruit Juice Concentration, Tomato Paste, Kiwi Puree ect.

1, treatment of industrial wastewater (environmental protection)

Concentration of industrial wastewater and recycling of water. Such as electroplating industry, paint production industry, pharmaceutical and pesticide industry, metal processing industry, paper industry and crude oil production industry and other sewage treatment. Remove organic and inorganic salts from the effluent. Turning waste into treasure. How to solve the problem of high-salt industrial wastewater reuse is a well-known problem. MVR evaporator is the best solution to deal with such industrial wastewater.

2, chemical industry

Production of hollow fiber molecules, treatment of water, purification of spices, production of chemical raw materials such as sodium chlorite and sodium persulfate, desalination of seawater, concentration and crystallization of organic additives, refining of the extract, and analysis of the reaction product into Solvents and products.

3, the pharmaceutical industry

China's pharmaceutical industry, is a traditional industry, the use of a large number of aging, old evaporator, not only reduce the quality of drugs, but also a lot of waste of energy, the urgent need to upgrade to reduce carbon dioxide emissions. MVR is also used to produce western medicine for the evaporation, concentration, crystallization and drying of Chinese medicine.

4, the food industry

In the deep processing of food industry, a large number of evaporation technology to achieve the function of dehydration. Such as concentrated corn steep liquor and extraction of glucose, amino acids and so on. Extraction of isopropanol from pectin, extraction and concentration of aromatics, fractionation of food and fermented fragrances, refining of solvents

5, wine industry

Wine industry China is an ancient industry. MVR evaporator can replace the old distillation equipment.

6, the milk industry

Because the milk industry needs low temperature, high degree of cleanliness, high degree of automation and other characteristics of the traditional evaporator is difficult to meet these requirements, so have the MVR evaporator development opportunities.

7, the concentration of the beverage industry

Tomato sauce, peach pulp, apricot pulp, carrot pulp, apple pulp, kiwi pulp

In summary, MVR applications are very wide, so that the traditional multi-effect evaporator applications, MVR evaporator can also be replaced. MVR evaporator and traditional evaporator, not only has a great advantage of energy saving and environmental protection, but also reduces operating costs, is the traditional multi-effect evaporator the best upgrading system. With the country's emphasis on environmental protection and energy conservation and emission reduction policies, MVR evaporator will replace the traditional evaporator, for the national environmental protection, energy conservation and sustainable development play a huge role. But also to the enterprise to bring the actual social and economic benefits.